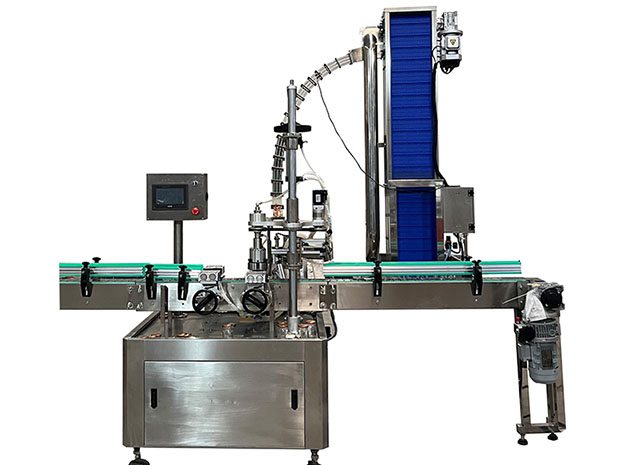

This capping machine is suitable for automatically screwing on various caps for glass or plastic bottles of all sizes. It uses a cap gripper to pick up caps from a scraper conveyor and completes the screwing process while the bottle rotates. The entire machine is PLC controlled with a touch-screen human-machine interface, making operation convenient and intuitive.

1. Utilizes Siemens components from Germany, ensuring stable operation and strong compatibility;

2. Automatic mold positioning and capping results in a high capping pass rate;

3. Mechanical gripper-type horizontal cap removal ensures stability and reliability;

4. Quick-installation mold design minimizes bottle type changeover time;

The equipment is highly intelligent, with flexible and parameterized design, and has a wide range of applications, being widely used in industries such as daily chemicals, food, chemicals, oils, health products, and cosmetics.

| Size of bottles: | 20-500 ml |

| Output: | 50-150 bottles/min |

| Diameter of caps: | φ20-65 mm |

| Diameter of bottles: | φ20-120 mm |

| Power supply: | 220V 60Hz |

| Power: | 1.5KW |

Overall dimensions: | 2160*1050*1900 mm |

| Weight | 650KG |