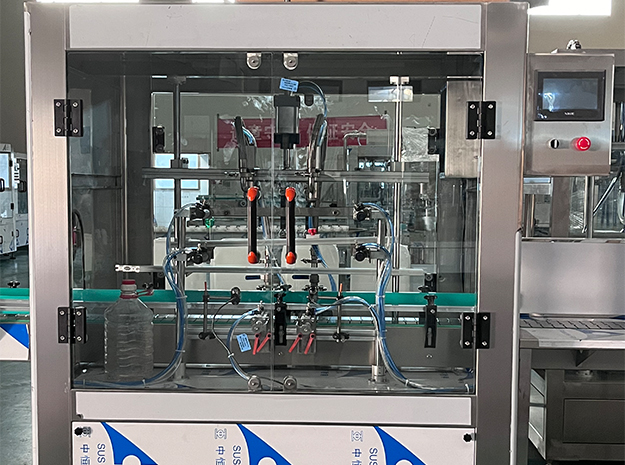

This filling machine is programmable controlled, integrating optics, mechanics, electronics, sensing, and pneumatic actuation. The piston cylinder is driven by a servo motor, ensuring accurate stroke positioning and allowing for both fast and slow filling speeds.

1. Easy adjustment: Filling parameters and a series of settings can be directly adjusted on the touch screen;

2. The piston cylinder is made of SUS316 material, which is durable and has good corrosion resistance;

3. The servo motor drives the dual lead screw lifting mechanism, making the piston stroke more precise and stabilizing filling accuracy;

4. It adopts an anti-drip filling head, which automatically discharges liquid from the collection tank after filling to avoid material contamination of the bottle.

The machine boasts a high degree of automation, is easy to adjust, and is suitable for filling various viscous materials in the vegetable oil, jam, honey, syrup, pharmaceutical preparations, suspensions, and daily chemical industries.

| Number of filling heads | 10heads |

| Filling range | 50-500ml |

| Production efficiency | 1000-2500B/H |

| Filling accuracy | ≤±0.5% |

| Applicable bottle size | Φ35~100mm,(H)50~300mm(Customization available outside the scope |

| working air pressure | 0.6-0.8Mpa |

| Gas consumption | 200L/min |

| Power supply | AC380V 50HZ 2.5KW |

| Equipment size | 1800×1400×2300mm |

| Equipment weight | 1200kg |